- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Outline

Automatic Wall-type High Speed Toilet Paper/Maxi Roll Rewinding Machine is for toilet paper roll /maxi roll processing.

Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log.

Then it can workwith cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And our machine can be special made according to clients’ requirements .

Functions and Features

1.This machine is for making toilet paper rolls, the whole structure is wall-type, which make machine running stable at high speed, and noiseless.

2.Perforation distance is adjustable to meet different distance needs.

3.Automatic core feeding system, automatic pushing the log after rewinding, then rewinding the new log again.

4. Automatic edge-trimming, glue spraying and sealing synchronously in one time. Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

5.Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

6.Adopts 4 pieces high Precision spiral knives, low noise, clear perforation, adopt gearbox to have bigger range.

7.Two wall type back stands, pneumatic lifting system, with wide driving flat belts; each jumbo roll can be adjusted independently.

8.Adopt jogging switches for wearing the paper, easy and safe to operate.

Technical Parameter

Jumbo Roll Max Width | 1200mm-2800mm |

Jumbo Roll Diameter | Φ1100mm-2000mm |

Jumbo Roll Inner Diameter | 3inches(76.2mm) (Other size can be specified) |

Perforation Distance | 4 anvil Blades(115mm)(Other size can be specified) |

Finished Product Diameter | Φ80~φ280mm |

Finished Product Core Diameter | φ38~φ76mm |

Production Speed | 0~230m/min |

Program Controller | PLC(Delta) |

Unwind Stands | 1 to 3 Stands(Need to be specified) |

Pneumatic System | 3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provide by user) |

Main Power | 14KW |

Machine Dimension | 7000*4000*1900(L*W*H) |

Machine Weight | About 7T |

Jumbo Roll can be used | 1 to 3 layers, 14-30gsm(Need to can be specified) |

Edge-Line Embossing(can be specified) | Steel to steel (Pneumatic Control) |

Embossing (can be specified) | The standard machine configuration with one set embossing unit, steel to rubber roller .( Double sets embossing unit is optional.) |

Voltage | 380V 50HZ |

Machine Main Description

Automatic feeding the core and unloading the roll automatically, machine can do both with core and without core

Automatic cutting and spray the glue to seal the roll tail

High precision perforation distance: 100-150mm, 4 anvil BladesSteel to rubber embossing unit. Rubber roller lifetime is about 4-5 years, Embossing depth is 0.8-1.2 mm according to embossing pattern

High precision perforation distance: 100-150mm, 4 anvil Blades

Steel to rubber embossing unit. Rubber roller lifetime is about 4-5 years, Embossing depth is 0.8-1.2 mm according to embossing pattern

Jumbo roll, 1-3 ply, 14-30 gsm toilet paper or kitchen towel, max jumbo roll diameter is 1100mm, inner core diameter is 76.2 mm.

synchronous belt

PLC and frequency inverter is Taiwan Delta, we use this system for more than 10 years, running very stable. If want to change other brand need to mention and add price difference.

Two wall type structure jumbo roll back stands, Pneumatic lifting the jumbo roll

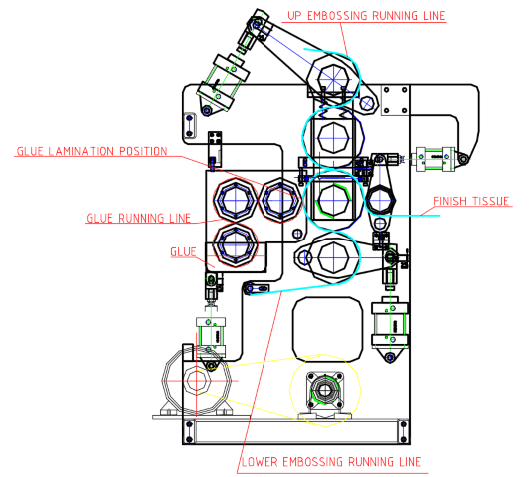

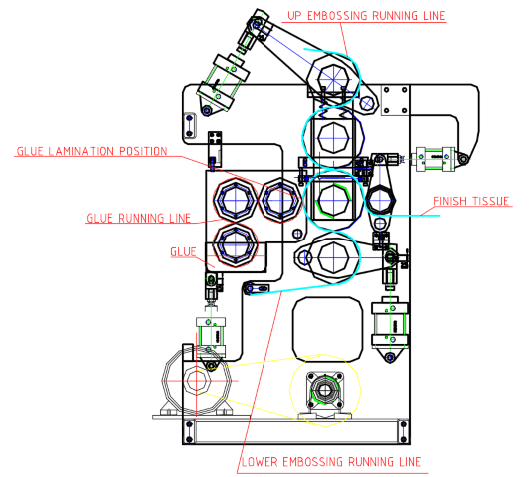

We adopt high grade glue lamination unit, wall type structure, embossing pattern point to point, glue volume control system to make the glue distribute evenly, and roller inside have heating system to make the paper dry quickly with glue, which can make embossing pattern looks deep and clear.

Finished Product Samples, roll diameter:Φ80-φ280mm, Roll Core Diameter: φ38-φ48mm, other size need to mentioned.

Outline

Automatic Wall-type High Speed Toilet Paper/Maxi Roll Rewinding Machine is for toilet paper roll /maxi roll processing.

Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log.

Then it can workwith cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And our machine can be special made according to clients’ requirements .

Functions and Features

1.This machine is for making toilet paper rolls, the whole structure is wall-type, which make machine running stable at high speed, and noiseless.

2.Perforation distance is adjustable to meet different distance needs.

3.Automatic core feeding system, automatic pushing the log after rewinding, then rewinding the new log again.

4. Automatic edge-trimming, glue spraying and sealing synchronously in one time. Leaving 10-18mm tail, easy to rewind again, so reducing shortcut waste and save the cost.

5.Adopts international advanced PLC programmable controlling technique, man-machine interface operation, data set and parametric fault shows on touch screen.

6.Adopts 4 pieces high Precision spiral knives, low noise, clear perforation, adopt gearbox to have bigger range.

7.Two wall type back stands, pneumatic lifting system, with wide driving flat belts; each jumbo roll can be adjusted independently.

8.Adopt jogging switches for wearing the paper, easy and safe to operate.

Technical Parameter

Jumbo Roll Max Width | 1200mm-2800mm |

Jumbo Roll Diameter | Φ1100mm-2000mm |

Jumbo Roll Inner Diameter | 3inches(76.2mm) (Other size can be specified) |

Perforation Distance | 4 anvil Blades(115mm)(Other size can be specified) |

Finished Product Diameter | Φ80~φ280mm |

Finished Product Core Diameter | φ38~φ76mm |

Production Speed | 0~230m/min |

Program Controller | PLC(Delta) |

Unwind Stands | 1 to 3 Stands(Need to be specified) |

Pneumatic System | 3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provide by user) |

Main Power | 14KW |

Machine Dimension | 7000*4000*1900(L*W*H) |

Machine Weight | About 7T |

Jumbo Roll can be used | 1 to 3 layers, 14-30gsm(Need to can be specified) |

Edge-Line Embossing(can be specified) | Steel to steel (Pneumatic Control) |

Embossing (can be specified) | The standard machine configuration with one set embossing unit, steel to rubber roller .( Double sets embossing unit is optional.) |

Voltage | 380V 50HZ |

Machine Main Description

Automatic feeding the core and unloading the roll automatically, machine can do both with core and without core

Automatic cutting and spray the glue to seal the roll tail

High precision perforation distance: 100-150mm, 4 anvil BladesSteel to rubber embossing unit. Rubber roller lifetime is about 4-5 years, Embossing depth is 0.8-1.2 mm according to embossing pattern

High precision perforation distance: 100-150mm, 4 anvil Blades

Steel to rubber embossing unit. Rubber roller lifetime is about 4-5 years, Embossing depth is 0.8-1.2 mm according to embossing pattern

Jumbo roll, 1-3 ply, 14-30 gsm toilet paper or kitchen towel, max jumbo roll diameter is 1100mm, inner core diameter is 76.2 mm.

synchronous belt

PLC and frequency inverter is Taiwan Delta, we use this system for more than 10 years, running very stable. If want to change other brand need to mention and add price difference.

Two wall type structure jumbo roll back stands, Pneumatic lifting the jumbo roll

We adopt high grade glue lamination unit, wall type structure, embossing pattern point to point, glue volume control system to make the glue distribute evenly, and roller inside have heating system to make the paper dry quickly with glue, which can make embossing pattern looks deep and clear.

Finished Product Samples, roll diameter:Φ80-φ280mm, Roll Core Diameter: φ38-φ48mm, other size need to mentioned.

Quanzhou, Fujian, China

Quanzhou, Fujian, China

Phone : +86-13615946593